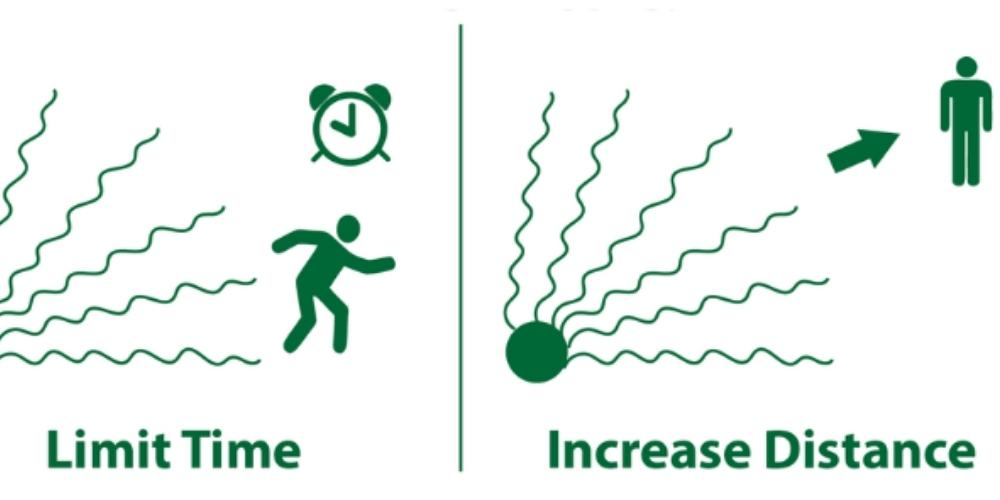

According to the Radiation Protection Guidance for Diagnostic and Interventional X-Ray procedures, a federal guidance report published by the United States Environmental Protection Agency (EPA), using shielding is one of the three pillars to effectively protect against X-rays. Along with shielding, the other two pillars are time and distance: less time spent near sources and greater distance from them means less radiation received. The goal is to limit the exposure of adults working with X-rays as much as possible with the help of the three pillars to make sure they will not be directly exposed. In this article, we’ll focus on the different types of radiation shielding materials, their effectiveness against radiation, their different features, and their different uses.

History of radiation protection

To understand why today’s use of X-ray is so controlled, we must go back to the beginning of the 20th century. X-ray started to become popular in medicine then; however, no one really understood the consequences of X-ray exposure.

Both physician and patient were exposed for hours during exams in a room completely flooded with radiation – they didn’t use any sort of enclosure, wearing no protection, or any form of shielding. It didn’t take long for doctors, engineers, and frequent users to start seeing side effects appearing on their hands, but because nobody understood how X-rays were working back then, everyone kept on using the modality without proper shielding.

A few years after initial use, the first premature deaths appeared, leading to the discovery that radiation protection and other such tools were a necessity. Some protective equipment was developed and made commercially available around 1905. One of the first tools were X-ray test hands. Until then, physicians were using their own to check if the X-ray unit was properly set up. Full body armor also appeared, made first of leather or leaded rubber. Additionally, lead barriers and radiation protection cabins were used more frequently.

Nowadays, we still use lead aprons to protect radiologists, their staff, and their patients. Fortunately, protective equipment has continued to evolve and radiologists now have more user-friendly, modern designs at their disposal. Practitioners can now benefit from a wide variety of lead glasses, head radiation protection, and lead gloves plus lighter radiation protection aprons to enhance their level of protection against harmful radiation.

Guidelines for radiology workers and patients

In the US, the EPA has the responsibility of providing recommendations and guidelines for federal facilities that perform diagnostic or interventional x-ray procedures. Private healthcare facilities are encouraged to consider those recommendations.

Moreover, states can have divisions in charge of radiation protection. For example, North Carolina has a Radiation Protection Section in its Department of Health and Human Services, publishing guidelines about the use and care of lead protective equipment for X-ray exposure. In these guidelines, we learn that both patients and workers (not standing in the primary beam) should wear gonadal shielding of not less than 0.25 mm of lead equivalence. If workers are standing in the primary beam, an adequate protection of 0.5 lead equivalence must be provided.

Lead radiation shielding

As we saw in the history of radiation shielding, lead was originally one of the first choices to protect against X-ray, mainly thanks to its softness, its malleability, and its resistance to corrosion. Lead is still largely used today for radiation protection equipment. To create an effective shield against radiation, manufacturers need to transform the lead by mixing it with binders and additives. The result is a flexible lead vinyl sheet that can be used to create wearable radiation shielding, such as lead aprons. To achieve the desired lead equivalency, the sheets are then layered in three standard levels of lead equivalency: 0.25mm, 0.35mm, and 0.5mm.

Lead shielding represents the standard in radiation shielding materials. It is an effective material to protect against scatter radiation, but it comes with a cost: garments can be quite heavy, and can therefore become very uncomfortable to wear for extended hours every day. Fortunately, other options exist today to meet the demand of frequent users looking for a lighter option.

Lead composite radiation shielding

With the evolution of science, and especially the understanding of how X-ray works, manufacturers began to create new composite shielding made from a blend of lead and other heavy metals that also attenuate radiation. The composition of the mixture varies from one maker to another, but they share a common goal: to achieve the same lead equivalency protection level while reducing the weight on the user.

Lead composite shielding offers many advantages. This material features improved longevity and can achieve a lead equivalency comparable to lead shielding while being up to 25% lighter.

Lead-free radiation shielding

This type of material is created in the same way as lead composite, but without the use of lead. The technique used is composite molding and it allows for the creation of materials offering the same amount of protection as lead composite shielding. They can be of different densities, impact strengths, flexibilities, and heat deflection temperatures.

Lead-free shielding brings many advantages. It is cost-effective, eco-friendly, durable, and non-toxic. Additionally, lead-free materials tend to be some of the lightest options on the market. Some options can be 18% lighter than standard lead. This is an important consideration for practitioners who use lead aprons for extended periods of time.

Which radiation shielding material should I use?

Each of the different types of radiation shielding materials shows advantages, and all should be considered before deciding. Healthcare facilities with sustainability in mind should consider electing lead-free shielding as an option for protecting radiologists, staff, and patients, as this could reduce the impact of lead on the environment.