A Quick Guide to Choosing the Right Ultrasound Paper for Medical Imaging Professionals

As a medical imaging professional, you know that the ultrasound paper you choose for your practice plays a pivotal role in ensuring high-quality imaging and accurate diagnoses. With a multitude of options in the market, making the right choice can be challenging. The ideal thermal paper enhances contrast, resolution, and detail in your ultrasound images, and ultimately paves the way for more precise screenings and better patient care. This guide aims to simplify your selection process by providing you with all the essential information on ultrasound thermal paper. We will delve into its history, discuss its significance in modern medicine, and help you navigate the myriad options available. By the end of this guide, you'll be well-equipped to choose the appropriate media paper for your practice.

What is Thermal Paper?

Ultrasound thermal paper, also known as sonography paper, is a specialty product used primarily in medical imaging. The paper's heat-sensitive coating changes color when heat is applied, which is how images are generated. This paper's specific use is not limited to the medical field; it's also used in retail for printing receipts and labels.

Using standard paper for ultrasound images is not recommended as it lacks the required heat sensitivity. Besides, ultrasound images are usually stored in DICOM format, which is incompatible with regular printers. Special ultrasound printers are needed for accurate reproduction of these medical images.

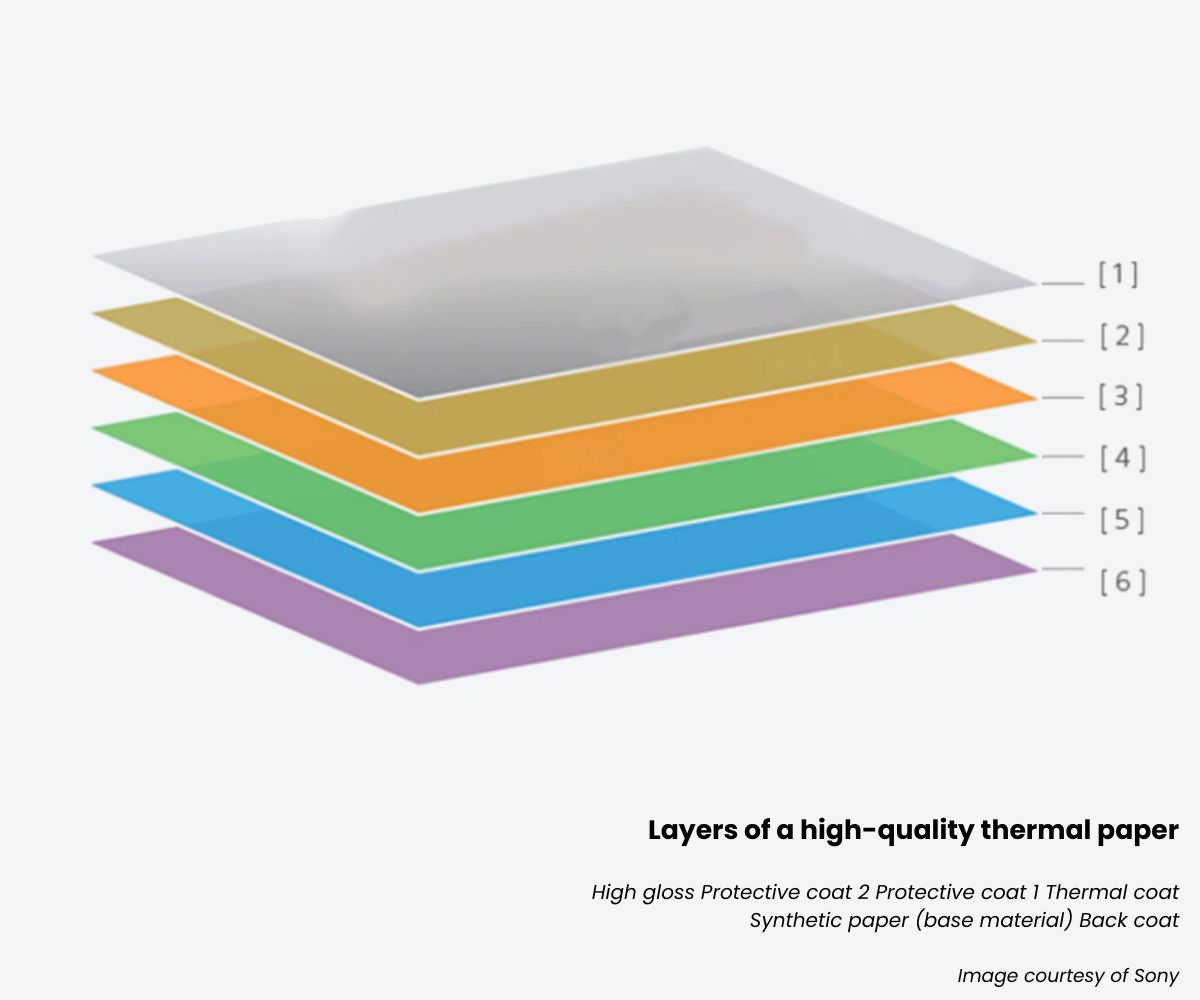

High-quality thermal paper has several layers including a glossy surface, protective coats, a thermal coat, the base paper, and a back coat. Each layer has a unique role to play in ensuring the quality and durability of the image.

Different Grades of Ultrasound Paper

Ultrasound thermal paper typically comes in three grades: standard, high-density, and high-gloss.

Standard and High-Density Ultrasound Papers: Both these grades consist of a back coat, yupo paper, thermal coat, and overcoat. High-density papers, however, offer higher accuracy, sharper images, and greater detail, making them perfect for critical diagnostic and treatment plans. High-density options include the Sony UPP-110HD High-Density Paper and the Mitsubishi K65HM Ultrasound Paper. For standard prints, many sonographers prefer the Mitsubishi K61B Ultrasound Paper or the Sony UPP-110S Standard Paper.

High-Gloss Ultrasound Papers: High-gloss paper, unlike standard and high-density, includes an additional gross coat and head cleaning coat. This layering ensures the paper's longer image durability, a polished finish, and a water-resistant feature. Reliable options for high-gloss ultrasound paper range from Sony UPP-110HG High-Gloss Paper and Sony UPP-84HG Ultrasound Paper to Mitsubishi K91HG Ultrasound Paper. Through understanding the different grades, medical imaging professionals can make a more informed choice based on their specific needs and the nature of their practice.

Choosing the Right Type of Paper for Specific Imaging Purposes

For medical imaging, the type of ultrasound paper used plays a crucial role in the accuracy and detail of the images. There are two key types of prints: black & white, and color.

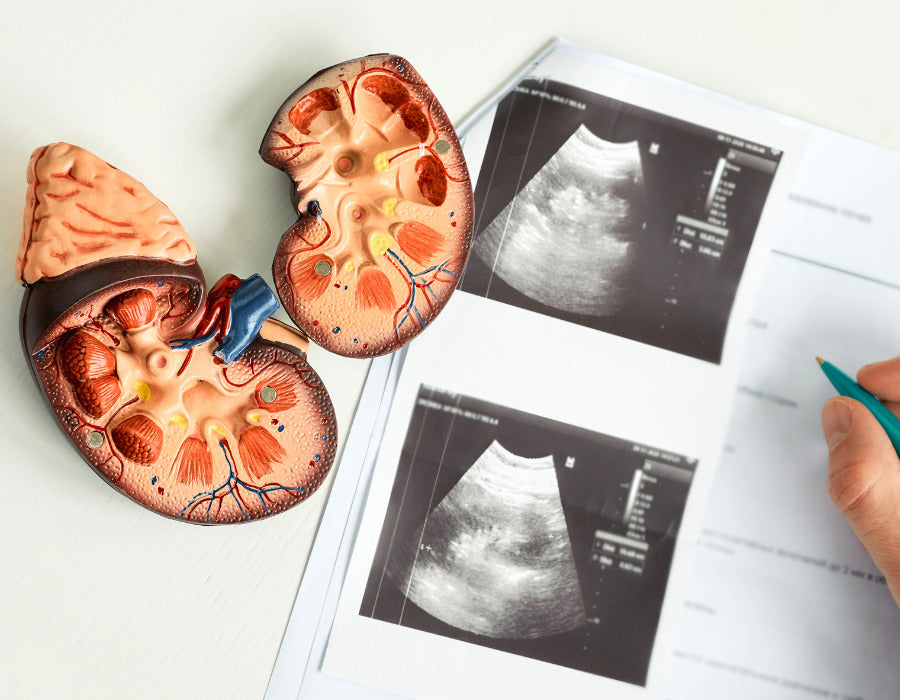

Black & White Ultrasound Paper: This is often utilized by gynecologists, urologists, and radiologists for diagnostics. It is critical for black & white images to have a wide range of grey tones, as these subtle shades determine the image's density. Achieving the correct grey scale through accurate tonal range reproduction is vital for a realistic and true representation of the anatomy.

Color Ultrasound Paper: This is generally preferred for 3D/4D screening in baby ultrasound centers. High-gloss color paper delivers highly detailed and exceptionally clear prints. Understanding the purpose of the imaging and the nuanced requirements of each paper type enables optimal image transfer from screen to paper.

Maintenance and Handling of Ultrasound Paper

Proper storage of ultrasound paper is imperative to ensure that images are preserved for a long time while maintaining their quality. According to Alliance Paper, the proper storage techniques for ultrasound paper include:

- Keep ultrasound prints in a dark and dry area: Exposure of thermal paper to the sun and conventional fluorescent light promotes fading and yellowing on the images.

- Maintain an average ambient temperature of less than 77°F and relative humidity less than 65%. If the paper is used continuously at temperatures of 104°F or above for more than 24 hours, pay attention to the ambient temperature and humidity to avoid compromising its quality.

- Refrain from using adhesives containing volatile organic solvents such as alcohols, esters, ketones, as they can cause color formation. Instead, use adhesives based on starch, PVA, or CMC, as they are harmless and recommended.

Choosing the right ultrasound paper ensures high-quality, accurate, and durable printed images. By understanding the various types of ultrasound paper, the importance of grayscale, and the proper storage techniques, you will be able to not only make the right choice but also make the most out of every thermal paper you use in your facility.

Besides choosing optimal media papers options from leading brands like Sony and Mitsubishi, it’s important to remember that the device you use also needs frequent service and maintenance to ensure its proper calibration and reliable prints. With these tips and insights in mind, you can confidently choose the right ultrasound paper for your needs and give your patients the best ultrasound experience.